EWSETe is an advanced monitoring and observation system for power grids developed by Patryk Lubomski. This system is based on the use of microphones and cameras installed at key points of the energy transmission network. Microphones record sounds generated by electrical devices such as transformers, power lines or substations. Cameras, on the other hand, record images related to the operation of these devices. All data collected by microphones and cameras is processed using advanced algorithms and artificial intelligence systems.

Nowadays, the reliability of power grids is critical to ensuring the continuity of energy supplies in a globalized and electrified world. In the event of errors in energy transmission, quick diagnosis and response are necessary to avoid serious failures and energy and component losses. In response to this challenge, Patryk Lubomski, an electrician running a sole proprietorship called „ELSTROM” in Belgium, developed and patented the innovative EWSETe system. In this description, we will take a closer look at this system and its significance for the electrical industry.

Below are some potential benefits from monitoring and analyzing sounds and images in the power grid:

Firstly, sound monitoring in the power grid can help detect faults and failures in real time. Microphones can record sounds such as cracks, pops and hums that may indicate improper equipment operation or damage. This allows network operators to quickly identify problems and take appropriate corrective action, contributing to increased reliability and efficiency of the grid.

Secondly, cameras installed in power grid infrastructure can provide visual information on infrastructure condition. Thermographic imaging can help identify overheating of grid components, which may indicate overload or damage. In addition, cameras can also help monitor infrastructure security, such as substations or high-voltage lines, contributing to protection against theft and acts of vandalism.

Thirdly, analysis of sounds and images from the power grid can help optimize energy management. For example, microphones can detect energy usage patterns such as noise generated by large devices or industrial installations, which may signal the need for more efficient energy solutions. In addition, cameras can identify areas with the highest energy demand and provide information on infrastructure use, allowing for better energy planning and distribution decisions.

Does microphone and camera be used in electricity to detect various potential problems?

Yes. Here are some examples:

1. Electric discharges: A microphone can record characteristic sounds of electric discharges such as cracks, bangs or snaps. Recording these sounds can help detect locations with insulation or short circuit issues.

2. Overheating: Microphone and camera can be used to detect overheating devices or connections. Overheating can cause characteristic sounds or visual indicators like cracks, smoke, sparks or color changes of electrical components. Recording these symptoms can help identify locations requiring immediate repair.

3. Vibrations: A microphone can detect abnormal vibrations in electrical devices. Abnormal vibrations may indicate mechanical issues with devices such as loose bearings, loose connections or improper engine operation.

4. Noise: Microphone and camera can record unusual noises generated by electrical devices. Improper noises may indicate damage, loose connections, surges or improper equipment operation.

5. Leaks: A camera can be used to detect fluid leaks, such as oil or coolant, which may indicate insulation or piping issues.

6. Electric arcs: A microphone can record sounds generated by electric arcs that occur when current jumps through air between two conductors. Recording these sounds can help identify locations with dangerous arcs or short circuits.

7. Asymmetric loads: Microphone and camera can be used to monitor loads on individual phases in an electrical system. Asymmetric loads may indicate issues with current flow evenness, which can lead to overheating and equipment damage.

8. Improper friction: A microphone can record sounds generated by friction or cracking between electrical components, indicating mechanical operation issues with devices.

9. Improper resonances: A microphone can detect improper resonances in electrical devices that can lead to damage or equipment failures.

10. Condition monitoring: Microphone and camera can be used for continuous condition monitoring of electrical devices and equipment. Recording sounds and images can help identify any abnormalities and suspicious behavior, enabling quick intervention and preventing larger problems.

How placing camera and microphone in power grids allows collecting data and inputting it live to a chart, allowing monitoring and predicting issues related to the power grid?

Cameras and microphones placed in electrical connections, transformers and generators can collect various types of data about these devices. Here are some examples:

1. Visual data: Cameras can record visuals of devices, allowing visual assessment of their condition. Elements like leaks, mechanical damage, overheating, condensation or other visual abnormalities can be observed.

2. Audio data: Microphones can collect sounds related to device operation. This allows detecting improper sounds like cracks, thuds, hisses or other noises indicating device issues.

3. Temperature: Thermal cameras can be used to measure temperature in connections, transformers and generators. This allows detecting excessive temperature rises indicating overloads, shorts or other issues.

4. Current: Cameras can be used to monitor current flow in electrical connections. This allows detecting improper current values, overloads or other power flow issues.

5. Vibration data: Microphones can also collect vibration data related to device operation. Increased vibrations may indicate mechanical issues like looseness, bearing damage or other irregularities.

This is just an example of data that can be collected using cameras and microphones. Additional information about collecting data using devices placed in electrical connections, transformers and generators includes:

1. Image analysis: Cameras can be used for image analysis and pattern/abnormality identification. Advanced algorithms and machine learning techniques allow automated detection and monitoring of specific elements or device states.

2. Sound detection: Microphones can be used to detect specific sounds related to device operation. Monitoring systems can be programmed to respond to sounds indicating issues like cracks, clicks or electric arcs.

3. Live streaming: Cameras and microphones can be used for live data streaming in real-time. This allows real-time monitoring of device conditions and quick corrective action if needed. Streaming data can go to on-site or cloud servers for advanced algorithm analysis and processing.

4. Integration with management systems: Data collected from cameras and microphones can be integrated into SCADA systems. It can be analyzed along with other grid data like energy usage, voltage, current or other parameters to obtain a holistic view of network and device conditions, facilitating corrective decisions and system optimization.

5. Anomaly detection: Using camera and microphone data, anomaly detection techniques can be applied to detect device operation irregularities. Machine learning algorithms can analyze data in real-time and detect patterns deviating from norms. Appropriate corrective actions can then be taken based on detected anomalies.

Would placing microphone and camera in distribution board with fuses, modules and connections provide many benefits to homeowners?

Yes, here are some benefits:

1. Device condition monitoring: Microphone and camera placed in the distribution board allow real-time monitoring of device conditions. Sounds and images can provide information about individual module, fuse and other element operations. This allows quickly detecting potential issues like overheating, voltage surges, shorts or other abnormalities.

2. Fault detection: Microphones and cameras can be programmed to respond to specific sounds and images indicating a fault or damage. For example, a microphone may detect an arc sound indicating a short, while a camera may detect sparking or leakage. This allows quick response to failures and minimized power supply downtime.

3. Troubleshooting: Microphone and camera placed in the distribution board can assist with troubleshooting. Sounds and images can provide clues about fault causes or abnormalities. For example, a cracking sound may indicate insulation damage, and a condensation image may indicate moisture ingress. This helps direct remedial actions appropriately and shorten downtime.

4. Accident prevention: Microphone and camera can help prevent accidents. They can detect dangerous situations like overloads, shorts or sparking that may lead to fires or electric shocks. With quick response to these signals, appropriate safety actions can be taken and risk minimized.

5. Auditing and monitoring: Microphone and camera can be utilized for auditing and monitoring the distribution board. Sounds and images can provide proof of system operation by recording startup, shutdown or other events. This allows monitoring system performance, identifying potential issues and increasing reliability.

6. Quick fault localization: Sounds and images collected using microphone and camera can aid swift fault localization. For example, cracking or sparking sounds/images may be identified as originating from a specific area in the distribution board. This allows focusing on the affected region and expediting fault identification and repair.

7. Environmental condition monitoring: Microphone and camera can provide information about environmental conditions in the distribution board. For example, a microphone may detect noise arising from vibrations or air turbulence indicating improper ventilation. A camera may detect dust, moisture or other factors affecting device operation. This allows monitoring and maintaining proper environmental conditions.

8. Remote management and control: Microphone and camera placed in the distribution board enable remote management and oversight. Sounds and images can be streamed live to a central monitoring system where technical staff can analyze them. This allows remotely monitoring equipment conditions, making repair decisions and performing remote operations for enhanced efficiency and optimization.

9. Documentation and reporting: Microphone and camera can serve documentation and reporting purposes. Sounds and images can be recorded as evidence of actions and equipment states. Reports can be created based on collected data usable for trend analysis, maintenance planning and future decision making.

10. Integration with automation systems: Microphone and camera can be integrated with automation systems. Sounds and images may be analyzed in real-time using advanced algorithms and machine learning techniques. Based on these analyses, automation systems can take decisions and execute operations like switching, powering or parameter adjustments.

11. Quick response to emergency situations: Sounds and images collected using a microphone and camera can help with rapid response to emergency situations. For example, an alarm or siren sound can be identified and appropriate actions taken immediately, such as evacuating staff or powering off. The camera can record event images, which can be useful for later analysis and reporting.

12. Maintenance optimization: Microphone and camera can help optimize equipment maintenance in the distribution board. Sounds and images can provide information about wear and tear, faults or other issues requiring maintenance. Based on this information, maintenance schedules, part replacements or other remedial actions can be planned, contributing to downtime minimization and cost reduction.

13. Staff safety improvement: Microphone and camera can contribute to improving the safety of staff working in the distribution board. Sounds and images can help identify situations that may endanger health and life. For example, a microphone may detect an explosion sound, and a camera may record a fire image. This allows staff to be quickly notified of danger and take appropriate remedial measures.

14. Operational process enhancement: Microphone and camera can contribute to enhancing operational processes in the distribution board. Sounds and images can provide information about device efficiency, load, energy usage and other parameters. Based on this information, operating parameters can be adjusted, energy usage optimized and operational efficiency increased.

15. Theft and sabotage prevention: Microphone and camera can help prevent theft and sabotage in the distribution board. Sounds and images can detect suspicious actions or intruders. For example, the sound of a lock being broken or the image of an unauthorized person in the distribution board may indicate an attempted theft or sabotage. This allows immediate actions to be taken to prevent potential losses.

16. Remote diagnostics: Microphone and camera placed in the distribution board can help diagnose problems remotely. Sounds and images can be transmitted to technical experts who can analyze them based on their knowledge and experience. This saves time and costs associated with technicians traveling to site and enables swift problem diagnosis and repair.

17. Training and education: Microphone and camera can be used for staff training and education related to the distribution board. Sounds and images can be recorded and used to create training and instructional materials. Staff can learn based on real situations and scenarios, contributing to increased knowledge and skills.

18. Resource optimization: Microphone and camera can help optimize resource use in the distribution board. Sounds and images can provide information about load, energy flow and other parameters. Based on this information, operating parameters can be adjusted, device placement planned and resource use optimized.

19. Remote monitoring: Microphone and camera placed in the distribution board enable remote monitoring. Sounds and images can be streamed live to a central monitoring system where they can be analyzed by technical staff. This allows remotely monitoring equipment conditions, detecting potential issues and taking appropriate remedial measures.

20. Integration with alarm systems: Microphone and camera can be integrated with alarm systems. Sounds and images can be analyzed in real-time, and in the event of an irregularity being detected, the alarm system may automatically send a notification to technical staff. This allows quick response to emergencies and minimizes losses.

Placing a microphone and camera in the distribution board with fuses, modules and connections provides many benefits including remote diagnostics, staff training, resource optimization, remote monitoring and integration with alarm systems. These benefits contribute to improved efficiency, safety and reliability of the electrical system.

What are the practical applications of the EWSETe system?

The EWSET finds application in various sectors where energy transmission plays a key role. Here are some examples of system applications:

1. Power plants: EWSET can be used in power plants, both conventional and renewable, to monitor and optimize energy transmission. The system allows quick detection of transmission faults, enabling swift response and minimized downtime in energy production. This allows power plants to operate more efficiently and reliably.

2. Transmission grids: Large transmission grids transporting energy over long distances can benefit from EWSET to monitor and manage energy flow. The system enables identification of areas at high risk of overloads and faults, allowing appropriate preventive actions to be taken. This allows transmission grids to operate more efficiently and reliably.

3. Energy distribution: In the energy distribution sector, EWSET can be used to monitor and manage the distribution grid. The system enables quick identification of faults and optimization of energy flow to minimize impact on end-users. This makes energy distribution more reliable and effective.

4. Critical infrastructure: EWSET can also find application for critical infrastructure such as hospitals, airports or industrial zones. The system allows monitoring and managing energy supply in these key sectors, ensuring reliability and safe operations. This enables critical infrastructure to function more smoothly and securely.

5. Industry: In industrial sectors where energy supply reliability and continuity are crucial, EWSET can be used to monitor and optimize energy transmission in factories, manufacturing plants and other industrial facilities. This optimizes energy usage and minimizes losses, translating to increased efficiency and profitability of industrial operations.

Is implementing such a system costly?

It’s worth noting that every EWSETe system implementation project is unique and costs may vary depending on specific requirements and project context. Therefore, it is important to thoroughly examine all factors and available options to estimate implementation costs.

Purchasing and integrating existing products when implementing the EWSETe system can provide many benefits.

The EWSETe system can be applied for both residential and commercial/industrial use.

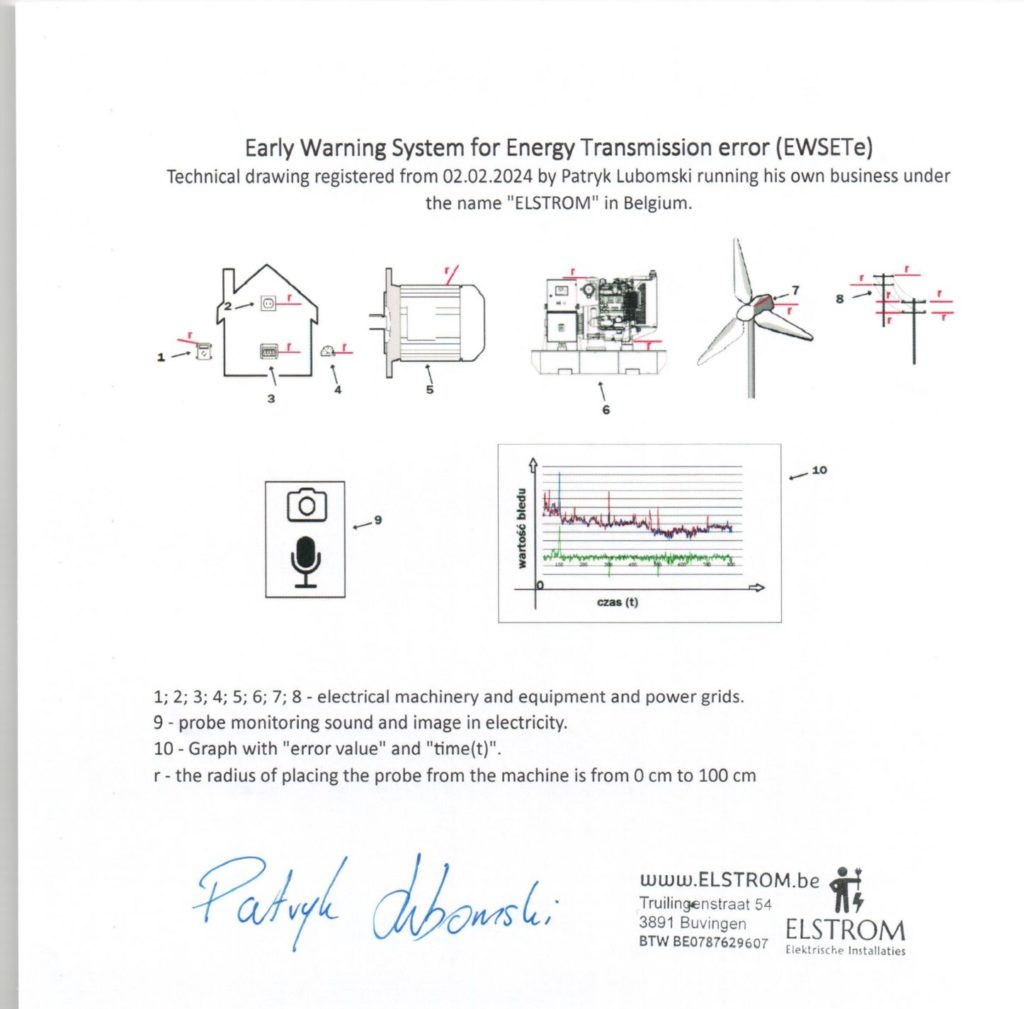

Early Warning System for Energy Transmission error (EWSETe)

Technical Drawing

Early Warning System for Energy Transmission error (EWSETe)

Patent Notice

The patent is protected in the territory of the Republic of Poland along with further stages in the European Union territory and will be protected internationally.

The owner is Patryk Lubomski running the business called „ELSTROM” in Belgium.

Truilingenstraat 54

3891 Buvingen

BTW BE0787629607

Any use of the patent without permission will result in claims for infringement of the right from utility model registration.